Mailbox:

info@hskcoltd.com

Mailbox:

info@hskcoltd.com

Hashimoto Precision Metal (Shenzhen) Ltd

Address: No. 25, Xinfa East Road, Xiangshan Community, Xinqiao street, Bao'an District, Shenzhen 518125, P.R.China

Tel: +86-755-27267875

Email: info@hskcoltd.com

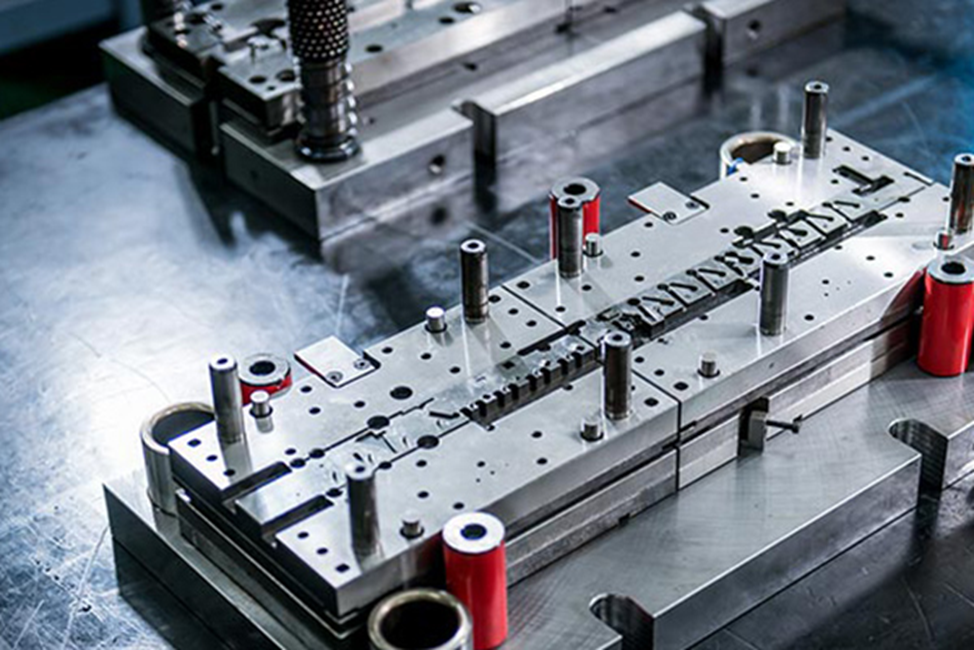

Stainless steel stamping is a metal-forming process used to produce complex shapes from sheets of stainless steel. Through stamping, intricate stainless steel components can be created by pressing or punching sheet metal into custom designs. This allows manufacturers to make durable stainless steel parts with precision and detail. Stainless steel stamping is commonly utilized in electronics stamping, medical devices, automotive, and other industries requiring corrosion resistance and durability in small parts. The versatility and formability of stainless steel through stamping have made it an essential process across many sectors.

Metal Stamping Materials – Overview of the Most Common Types

There are several different metal stamping material types available. Understanding the properties of common metals allows manufacturers to select the optimal material for their electronics stamping needs. The most common types include:

1. Stainless Steel Alloy

As implied by its name, stainless steel alloy offers outstanding corrosion resistance through the addition of chromium. It maintains strength even after forming and is easy to paint or polish for decorative finishes.

2. Copper Alloy

Copper alloys such as brass and bronze exhibit higher malleability than steel. They possess good machining capabilities and lustrous looks suited for decorative uses. However, they are more expensive than steel.

3. High Nickel Alloy

Materials with nickel content above 25% have ultra-high corrosion resistance, almost as good as stainless steel. They maintain properties even at cryogenic temperatures, but the price is considerably higher.

4. Aluminum Alloy

Being lightweight yet rigid, aluminum stampings find applications where weight savings are critical. Different alloying elements provide a range of strengths and corrosion-resistant properties.

5. Tinplate

Made of steel and plated with tin, tinplate resists corrosion and enables easy painting and printing on stamped parts. It is commonly used for food and chemical packaging.

What is Stainless Steel Stamping?

Stainless steel stamping refers to using stamping dies and presses to shape stainless steel sheet metal into precise components. By applying great pressure, the sheet metal plastically deforms into the die cavity outlines. The stainless steel maintains its corrosion-resistant properties through this forming process.

Stainless steel stamping differs from other electronics stamping methods in its complex detail capabilities. Drawing and stretching involve simpler part profiles, whereas stamping facilitates intricate contours, holes, and inward angles in a single press stroke. This provides design flexibility and complexity that is challenging to achieve via other metalworking. As electronics and appliances require increasingly miniaturized parts, stainless steel stamping satisfies that need for small, accurate components.

Advantages of Stainless Steel Stamping Parts

The many advantages of stainless steel stamping parts have made them very popular across different industries. Key advantages include:

1. Corrosion Resistance and Longevity

Stainless steel withstands rust and corrosion due to chromium content. Stamped parts maintain properties throughout a product’s lifespan, reducing replacement costs.

2. Precision and Durability

Tight tolerances between 0.02mm and 2.00mm can be achieved through electronics stamping. Formed parts withstand stresses and impact forces from regular use.

3. Aesthetic Appeal and Design

Stamped contours emulate modern designs. Polishing brings out steel’s luster for decorative presence in devices and appliances.

4. Electrical Conductivity and Thin-Gauge Capability

While stainless steel may not be the best conductor of electricity, it still conducts electricity to a sufficient degree for various applications involving circuit boards and electrodes. Its conductivity might not match materials like copper, but it is often used when its other properties, such as corrosion resistance, are required in conjunction with moderate electrical conductivity.

(Copyright photo from https://www.freepik.com/free-vector/chrome-gradient-shapes_44156858.htm )

Hashimoto Precision Offers Quality Metal Stamping Supplies

Headquartered in Japan, Hashimoto Precision has become a premier global provider of precision metal stampings after beginning as a small stamping workshop over decades. What started as a humble family shop has expanded greatly over the decades into a major multinational operation.

Hashimoto Precision’s electronics stamping expertise lies in producing miniature parts of intricate designs from a wide variety of metal materials. Our experience across automotive, electronics, medical, telecommunications, and other sectors has equippedus with versatile stamping solutions catered to diverse industry needs. Some key advantages of the manufacturer include:

ü Quality and Certifications: ISO9001, ISO14001, and TS16949 quality certifications for stringent processes.

ü Cutting-Edge Technology: Robotic laser welding and automated inspection systems ensure precision.

ü Customization Capabilities: Dedicated engineering support for developing customized electronics stamping solutions.

ü Global Manufacturing and Support: Locally-based sales and tech support across major international markets.

ü Commitment to Sustainability: Zero-waste strategies and green initiatives and material sourcing.

With these strengths, Hashimoto Precision delivers exceptional stamping supplies with proven reliability to clients worldwide.

Conclusion

Overall, stainless steel stamping is a versatile metal forming process that enables intricate part profiles through high pressure. The material properties of stainless steel make it suitable for withstanding corrosion and wear and tear. Stamped components exhibit strength, precision, and aesthetic qualities valued across industries. Leading manufacturers like Hashimoto Precision have mastered stainless steel stamping through many decades of experience. With advanced facilities, certified quality management systems, and customized capabilities, Hashimoto Precision delivers premium metal stamping supplies and solutions. Explore our website to discuss working with a seasoned industry leader in precision stamping.

Hashimoto Precision Metal (Shenzhen) Ltd

Address: No. 25, Xinfa East Road, Xiangshan Community, Xinqiao street, Bao'an District, Shenzhen 518125, P.R.China

Tel: +86-755-27267875

Email: info@hskcoltd.com

Follow us

Copyright ? 2021 Hashimoto Precision Metal (Shenzhen) Ltd

Address: No. 25, Xinfa East Road, Xiangshan Community, Xinqiao street, Bao'an District, Shenzhen 518125, P.R.China

Tel: +86-755-27267875

Mailbox